Riveting

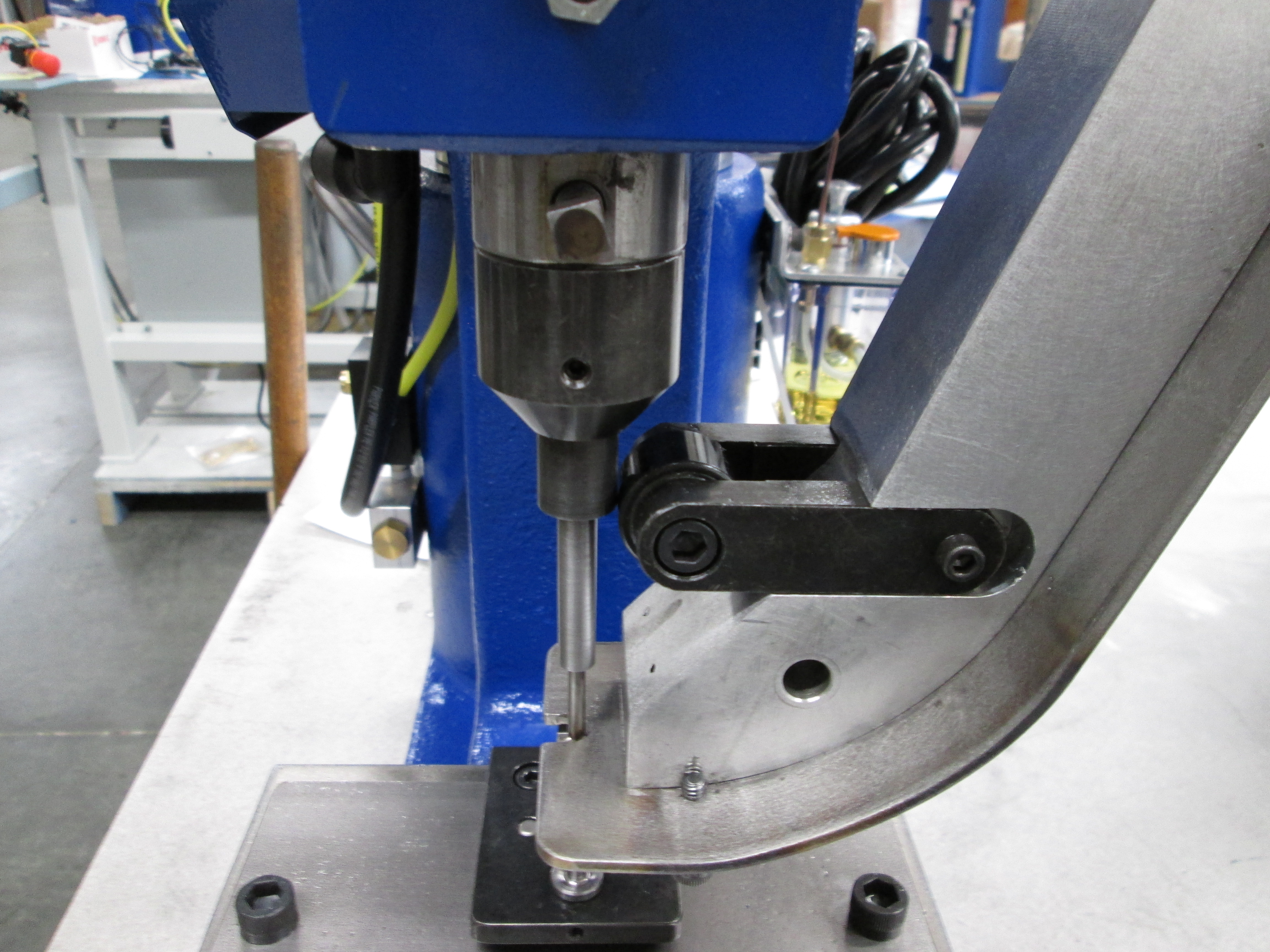

An example of our work:

Rivets are permanent fasteners that feature smooth cylindrical shafts with a head on one end. Manual installation requires the use of pre-punched or pre-drilled holes into which the rivet is inserted. Once it is in position, its exposed end is hammered to secure it in place.

Riveting machines serve as a modern alternative to manual riveting, allowing for easier, faster, and more consistent installation. They are available in many variations—such as manual feed or automatic feed—to suit different manufacturing applications.

RIVETING MACHINES AT JORACO PRESS COMPANY

Joraco Press has served industry with innovative products and superior service for over 75 years. For riveting applications, we provide tubular/eyelet rivet machines built around our standard line of TOGGLE-AIRE® Series Pneumatic Presses. These machines offer the same reliability and ease of maintenance expected of us and give customers the convenience of interchangeable parts between the rivet machines and pneumatic press line.

Our Model 1030R is capable of handling soft steel or brass tubular rivets up to 3/8 inch in diameter, while the Model 1530R is suited for heavier materials such as stainless-steel. Both machines offer automatic hopper feeding, non-binding and jamming feeding heads, and a fully pneumatic press integrated with AC powered cam-belt driven rivet heads.

FOR ADDITIONAL INFORMATION ABOUT OUR RIVETING MACHINES OR ASSISTANCE CHOOSING THE BEST MACHINE FOR YOUR APPLICATION, CONTACT US TODAY.