STANDARD PRODUCTS

Joraco Press Company manufactures pneumatic presses for industrial applications. They can be manually operated safely using our SYNCHRO-SIG™ Two Hand, Anti-Tie Down controller or set up in an automated line complete with a PLC or valved PLC-ready for integration into an existing line. Our benchtop pneumatic presses are manufactured to order and can be quoted with custom dimensions to accommodate a specific open height, throat and/or stroke as well as custom bolster plate measurements and hole patterns. Die Sets, flange adapters, and various custom features are all quoted upon request. Our engineering team is available to recommend the press best suited for your application needs.

TOGGLE-AIRE® Series Pneumatic Toggle Presses

Joraco Press Company TOGGLE-AIRE® Series pneumatic toggle presses combine the mechanical advantages of levers and toggles. Forces produced don’t rely on ram impact; rather, it builds as the ram reaches the bottom of the stroke, and effects a shockless, powerful squeeze, regardless of ram speed. Additionally, it is highly efficient- a TOGGLE-AIRE® Series Model 1030 press is 300% more powerful than a comparable cylinder-sized DIRECT-AIRE® Series press, yet only 58% of the air is needed. Most importantly, the stroke is very precise with +/-.001” repeatability.

DIRECT-AIRE® Series Pneumatic Presses

Joraco Press Company DIRECT-AIRE® Series presses feature a straight pneumatic cylinder for applications requiring full force over the entire 4.5” stroke. They are suitable for a wide range of manual and semi-automatic operations up to 10,000lbs of constant force, in either a C-Frame or H-Frame configuration. Known for their efficiency, economy, and customizability, the DIRECT-AIRE® Series is an air-actuated workhorse for many industries and applications.

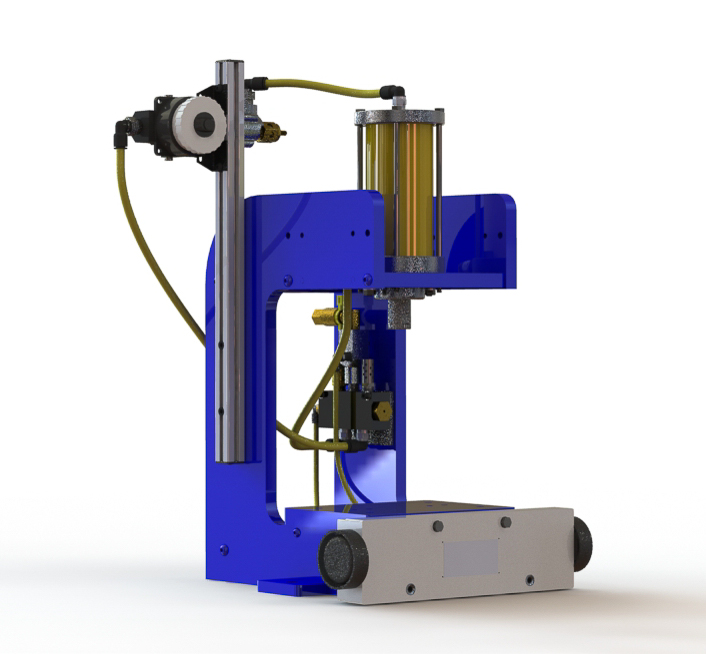

HYDRO-AIRE™ Series Hydro-Pneumatic Presses

Joraco Press Company HYDRO-AIRE™ Series presses offer clean, reliable, and accurate results. This Hydro-Pneumatic (HP) Press Series is a much cleaner alternative to a hydraulic press and offers the same advantages. It is fully contained with no fluid reservoirs or hydraulic lines, and features rapid advance with automatic power stroke. Suitable for a wide range of manual and semi-automatic assembly operations, this press is offered with a standard 4” stroke with 1/2″ power stroke, providing from 2 to 16-tons of force, in both C-Frame and H-Frame Configurations. Manufactured in the USA from steel plate.

INDEX-AIRE™ Series Rotary Indexing Machines

Joraco Press Company INDEX-AIRE™ Series rotary indexing press machines offer versatile, efficient, and simple automatic operation in small areas. The INDEX-AIRE™ Series Model 2000 is an air-actuated all-in-one press and rotary indexing combo with six (6) stations that is based on our TOGGLE-AIRE® Series Model 1030 or Model 1530 toggle press. For larger and more specific applications, the INDEX-AIRE™ Series Model 1011RT is customizable from 4 to 24 servo-actuated stations and can be equipped with one or more C-Frame TOGGLE-AIRE®, DIRECT-AIRE®, and/or HYDRO-AIRE™ Series presses. All INDEX-AIRE™ rotary indexing machines can be customized to specific applications and needs including interchangeable tool plates, as well as the addition of many styles of automation components.

Packages

Every Joraco Press Series has a list of Packages, Options, and Accessories that will aid in the specific requirement of the application. Packages included Force Monitoring Machines, Rivet Machines, Heat Stamp Machines, Crimping Machines, Medical-grade Clean-Room Machines, and completely Custom turn-key machines. Standard OEM installed Options include PLC control, Filter, Regulator, & Lubricator, One-Shot Lubrication, Adjustable Stroke and Hard Stop, EZ-Dial Force Regulator, Non-Rotating Ram, Programable Dwell Timer, and more. Finally, Accessories from Joraco make operation easier, including custom Welded Steel Press Stands, J-Series Die Sets, Optical Touch controllers, Light Curtains, Three-Sided Guarding, Speed Control Mufflers, Parts Counters, Shank Adapters, and Fine-Adjustment Wheels.

Options & Accessories

Every Joraco Press Series has a list of Packages, Options, and Accessories that will aid in the specific requirement of the application. Packages included Force Monitoring Machines, Rivet Machines, Heat Stamp Machines, Crimping Machines, Medical-grade Clean-Room Machines, and completely Custom turn-key machines. Standard OEM installed Options include PLC control, Filter, Regulator, & Lubricator, One-Shot Lubrication, Adjustable Stroke and Hard Stop, EZ-Dial Force Regulator, Non-Rotating Ram, Programable Dwell Timer, and more. Finally, Accessories from Joraco make operation easier, including custom Welded Steel Press Stands, J-Series Die Sets, Optical Touch controllers, Light Curtains, Three-Sided Guarding, Speed Control Mufflers, Parts Counters, Shank Adapters, and Fine-Adjustment Wheels.

TOGGLE-AIRE® Series Pneumatic Toggle Presses

Joraco Press Company TOGGLE-AIRE® Series pneumatic toggle presses combine the mechanical advantages of levers and toggles. Forces produced don’t rely on ram impact; rather, it builds as the ram reaches the bottom of the stroke, and effects a shockless, powerful squeeze, regardless of ram speed. Additionally, it is highly efficient- a TOGGLE-AIRE® Series Model 1030 press is 300% more powerful than a comparable cylinder-sized DIRECT-AIRE® Series press, yet only 58% of the air is needed. Most importantly, the stroke is very precise with +/-.001” repeatability.

DIRECT-AIRE® Series Pneumatic Presses

Joraco Press Company DIRECT-AIRE® Series presses feature a straight pneumatic cylinder for applications requiring full force over the entire 4.5” stroke. They are suitable for a wide range of manual and semi-automatic operations up to 10,000lbs of constant force, in either a C-Frame or H-Frame configuration. Known for their efficiency, economy, and customizability, the DIRECT-AIRE® Series is an air-actuated workhorse for many industries and applications.

HYDRO-AIRE™ Series Hydro-Pneumatic Presses

Joraco Press Company HYDRO-AIRE™ Series presses offer clean, reliable, and accurate results. This Hydro-Pneumatic (HP) Press Series is a much cleaner alternative to a hydraulic press and offers the same advantages. It is fully contained with no fluid reservoirs or hydraulic lines, and features rapid advance with automatic power stroke. Suitable for a wide range of manual and semi-automatic assembly operations, this press is offered with a standard 4” stroke with 1/2″ power stroke, providing from 2 to 16-tons of force, in both C-Frame and H-Frame Configurations. Manufactured in the USA from steel plate.

INDEX-AIRE™ Series Rotary Indexing Machines

Joraco Press Company INDEX-AIRE™ Series rotary indexing press machines offer versatile, efficient, and simple automatic operation in small areas. The INDEX-AIRE™ Series Model 2000 is an air-actuated all-in-one press and rotary indexing combo with six (6) stations that is based on our TOGGLE-AIRE® Series Model 1030 or Model 1530 toggle press. For larger and more specific applications, the INDEX-AIRE™ Series Model 1011RT is customizable from 4 to 24 servo-actuated stations and can be equipped with one or more C-Frame TOGGLE-AIRE®, DIRECT-AIRE®, and/or HYDRO-AIRE™ Series presses. All INDEX-AIRE™ rotary indexing machines can be customized to specific applications and needs including interchangeable tool plates, as well as the addition of many styles of automation components.

Packages

Every Joraco Press Series has a list of Packages, Options, and Accessories that will aid in the specific requirement of the application. Packages included Force Monitoring Machines, Rivet Machines, Heat Stamp Machines, Crimping Machines, Medical-grade Clean-Room Machines, and completely Custom turn-key machines. Standard OEM installed Options include PLC control, Filter, Regulator, & Lubricator, One-Shot Lubrication, Adjustable Stroke and Hard Stop, EZ-Dial Force Regulator, Non-Rotating Ram, Programable Dwell Timer, and more. Finally, Accessories from Joraco make operation easier, including custom Welded Steel Press Stands, J-Series Die Sets, Optical Touch controllers, Light Curtains, Three-Sided Guarding, Speed Control Mufflers, Parts Counters, Shank Adapters, and Fine-Adjustment Wheels.

Options & Accessories

Every Joraco Press Series has a list of Packages, Options, and Accessories that will aid in the specific requirement of the application. Packages included Force Monitoring Machines, Rivet Machines, Heat Stamp Machines, Crimping Machines, Medical-grade Clean-Room Machines, and completely Custom turn-key machines. Standard OEM installed Options include PLC control, Filter, Regulator, & Lubricator, One-Shot Lubrication, Adjustable Stroke and Hard Stop, EZ-Dial Force Regulator, Non-Rotating Ram, Programable Dwell Timer, and more. Finally, Accessories from Joraco make operation easier, including custom Welded Steel Press Stands, J-Series Die Sets, Optical Touch controllers, Light Curtains, Three-Sided Guarding, Speed Control Mufflers, Parts Counters, Shank Adapters, and Fine-Adjustment Wheels.

16 Ton Pneumatic Toggle Press

TOGGLE-AIRE® Series Model 3530

The Model 3530 pneumatic toggle press is capable of producing over 36,000LBS of force at 100PSI. Its precision benchtop design operates with a repeatability of .001″ and can be cycled more than 80 strokes per minute in some configurations. Faster cycle times are available on presses with shorter than standard strokes.

Our TOGGLE-AIRE® Series pneumatic toggle presses are supplied complete with our Synchro-Sig Series Two-Hand Actuator (SS-PB-18), but are also completely compatible with automated lines, and available with optional control systems. Our engineering department is available to supply technical information to OEMs as well as in-house machine builders if you are considering the press as a component in your cell or automated line.

10 Ton Pneumatic Toggle Press

TOGGLE-AIRE® Series Model 2530

The Model 2530 pneumatic toggle press is capable of producing over 24,000LBS of force at 100PSI. Its precision benchtop design operates with a repeatability of .001″ and can be cycled more than 80 strokes per minute in some configurations. Faster cycle times are available on presses with shorter than standard strokes.

Our TOGGLE-AIRE® Series pneumatic toggle presses are supplied complete with our Synchro-Sig Series Two-Hand Actuator (SS-PB-18), but are also completely compatible with automated lines, and available with optional control systems. Our engineering department is available to supply technical information to OEMs as well as in-house machine builders if you are considering the press as a component in your cell or automated line.

5 Ton Pneumatic Toggle Press

TOGGLE-AIRE® Series Model 1530

The Model 1530 pneumatic toggle press is capable of producing over 11,000LBS of force at 100PSI. Its precision benchtop design operates with a repeatability of .001″ and can be cycled more than 120 strokes per minute in some configurations. Faster cycle times are available on presses with shorter than standard strokes.

Our TOGGLE-AIRE® Series pneumatic toggle presses are supplied complete with our Synchro-Sig Series Two-Hand Actuator (SS-PB-18), but are also completely compatible with automated lines, and available with optional control systems. Our engineering department is available to supply technical information to OEMs as well as in-house machine builders if you are considering the press as a component in your cell or automated line.

3 Ton Pneumatic Toggle Press

TOGGLE-AIRE® Series Model 1030

The Model 1030 pneumatic toggle press is capable of producing over 6,000LBS of force at 100PSI. Its precision benchtop design operates with a repeatability of .001″ and can be cycled more than 120 strokes per minute in some configurations. Faster cycle times are available on presses with shorter than standard strokes.

Our TOGGLE-AIRE® Series pneumatic toggle presses are supplied complete with our Synchro-Sig Series Two-Hand Actuator (SS-PB-18), but are also completely compatible with automated lines, and available with optional control systems. Our engineering department is available to supply technical information to OEMs as well as in-house machine builders if you are considering the press as a component in your cell or automated line.

NEED MORE?

CUSTOMIZATION

Automated Industrial Machine, Inc is the proud owner and manufacturer of the Joraco Press Company. In addition to Joraco, AIM is a vertically integrated manufacturer; we have an experienced team of machinists, operators, integrators, and engineers that provide industrial solutions for any application your company needs. Consider us a one-stop, factory-direct partner for your manufacturing project.

Whether you are looking for single use or full automation, we can provide turn-key solutions in the form of machines, work cells, and workstations. Alternately, we can research, design, test, and produce custom tooling and die sets. Recently, AIM has introduced the latest technology in manufacturing, such as 3D Printing, CAD Modeling and Visualization, and CAD-CAM software, to speed up all phases of production. As a culmination of all these resources, Automated Industrial Machine, Inc is positioned to be the partner your project needs.

OUR CUSTOMERS

Our customers produce almost every kind of industrial, commercial, and consumer product available in the world market. These customers, and hundreds more, put their trust in Joraco Press Company's reliability, precision and factory direct service - so can YOU!