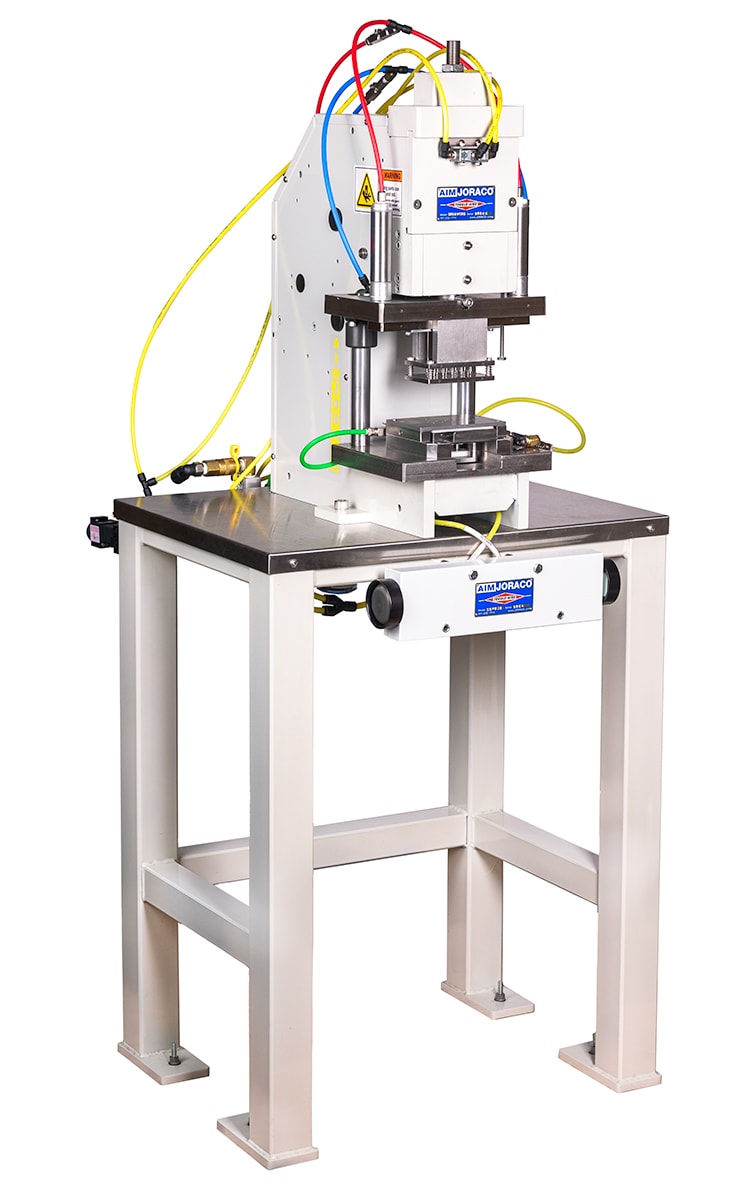

Clean Room Presses

Joraco Press Company’s benchtop pneumatic presses for Clean Rooms (CLEAN) offer versatile solution applications. Most of our standard product line can be configured as a Clean Room Press. We divide the Package into three levels based on Exhaust Air and Stainless Steel use. Level 1 complies with ISO Class 5 Level 100 air exhaust standards for use in clean room environments. Levels 2 and 3 will increase the amount of Stainless Steel we use in construction, from contact surfaces only to full SS construction. We invite you to tell us your project specifications so that we can quote a custom solution for your application requirements. Our Manufacture to Order sales model allows us to work within your project specifications!

In addition to air filtration and stainless steel, Joraco Press Clean Room Packages feature upgraded powder coated finishes, as well as passivation of stainless components. We can match the Clean Room levels to any customization, tooling, guarding, and accessories. Furthermore, we reduce noise by 40dB and restrict the use of lubricants.

Options Include:

- Adjustable Output

- Filter, Regulator, Lubricator (FRL) – Cleanroom Compliance

- Dwell Timer

- Non-Rotating Ram

- Adjustable Ram Speed Control

- Optical “No-Touch” Anti-Tie Down Actuation

- Special FDA Powder Coat Finish

- Clean Room Guarding, Bevel and/or Sealants

Can be PLC Ready for automated setups and Force Monitoring Packages available!

- Particle density for particle of 0.3µm or larger is less than 3.5 particles

- Press noise silencing effect of 40dB(A) or more

- PTFE – No Lubrication Bearing Surface

- 400 Series Stainless Steel

- (includes all fasteners, ram and precision ground platen)

- Internally contained lubrication for ram

| Clean Room Press Attributes: | Markets Served with Our Clean Room Press: | Applications for Our Clean Room Press: | Force Used When Applying Our Clean Room Press: |

|---|---|---|---|

|

|

|

|