Punching

An example of our work:

Joraco Press Company Provides a Solution for Specialty Filter Manufacturer With Their TOGGLE-AIRE® Series Model 3530 Press

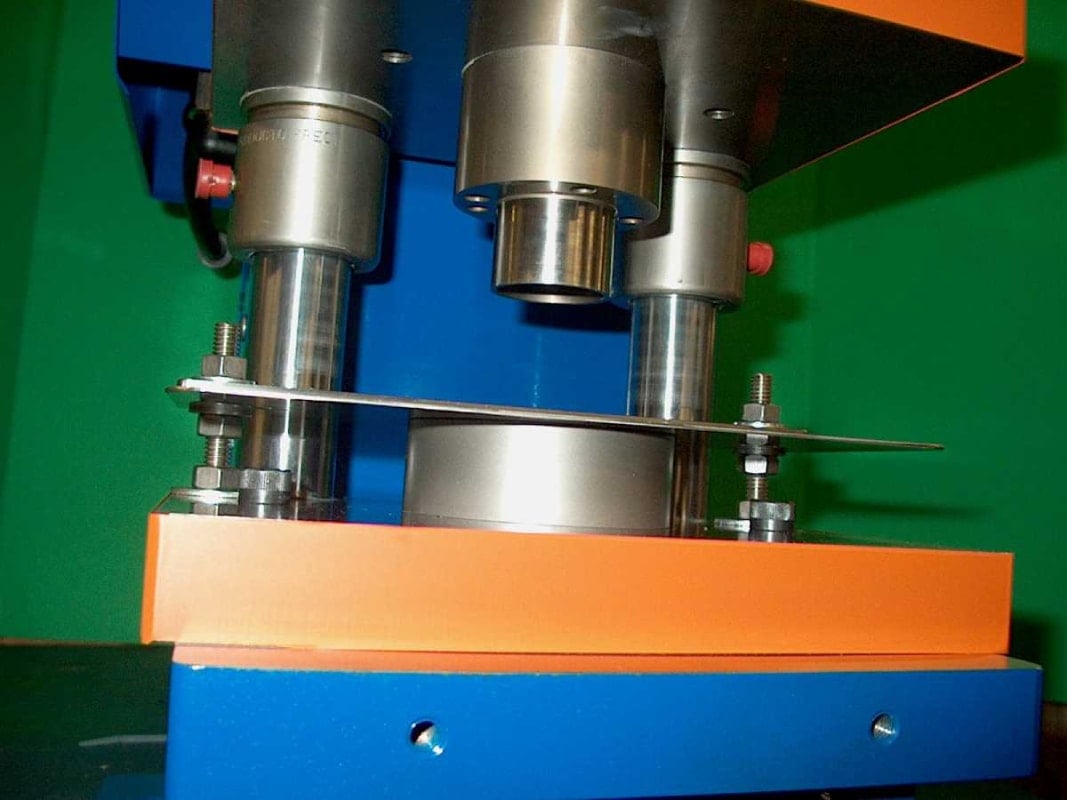

At Joraco Press Company, we provided a top manufacturer of specialty filters with a turnkey solution for a technically sophisticated punching application. Automated Industrial machine, Inc and Joraco Press Company's automation specialists worked together to engineer and manufacture a product that would comply with strict clean room standards and was based on Joraco’s 16 ton TOGGLE-AIRE® Series Model 3530 design. The solution also incorporates an INDEX-AIRE Series Model 1011RT servo-indexed rotary indexer and an optical sensing system for quality control. The dimensions occupy a compact 33.75″ x 20.0″ footprint and stands 65.0″ high, which is the same used in the production stainless steel mesh filters for an aerospace application.

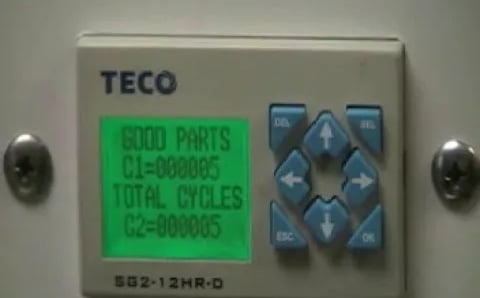

The Model 3530 is capable of producing over 36,000lbs of force at 100PSI. It operates on 50 to 125lbs of air pressure with a repeatability of +/- .001” and capable of up to 80 stokes per minute. It has low air consumption and a controlled squeeze to over 20,000 lbs. at 80 psi. There are replaceable bronze/PTFE bushings used throughout the entire linkage assembly and the 8” x 10” precision ground bolster plate is removable to accommodate tooling requirements. This equipment punches extremely small, difficult to manipulate woven and pleated stainless-steel mesh sheets. The machine loads the mesh into nests on a rotary indexer, and as the indexer rotates, a vision system verifies that the part is loaded and oriented correctly. If the mesh is seated properly, the press actuates and punches a hole in the sheet. A second automated vision system takes measurements and monitors tolerances, and if a part is defective, it is ejected into a separate bin.

AIM and Joraco's solution significantly enhanced the manufacturing process of the manufacturer. By implementing the first optical sensing systems to provide feedback on part presence and orientation and the second to assess quality, we automated the entire process. The stainless steel, clean room compatible construction eliminates the possibility of contamination leaking into the manufacturing area and compromising the integrity of filters as they are processed.